See what I found... Looking Outside Ngahue IV

Propulsion

For most of the building period, HR53s were

fitted with a Volvo-Penta TAMD41-B/H engine, which weighs in at approximately 455 kg and produces a respectable 145 HP. The "H" designates the

heavy-duty models, specifically designed for trucks and busses, as they don't exceed 2500 rpm. The last HR53 units to be built were fitted

with a much more modern VP D3-110 engine. The TAMD engine (see picture) is essentially a 6 cylinder 3.59 litre Volvo turbo diesel bus or truck

engine which has been "marinised". The engine is fitted with a hydraulic marine gearbox which is water cooled, as is the turbo charger. The whole

cooling circuit is long and complex. Especially if the boat has not been used for some time, it's a good idea to check the big VETUS water strainer,

where sometimes we need to add water to overcome air pockets which may have developed over such longer periods of non-use! We systematically check

that there's water coming out of the exhaust, having - by omission - succeeded in 'burning' one impeller in our beginning days of owning the boat!

For most of the building period, HR53s were

fitted with a Volvo-Penta TAMD41-B/H engine, which weighs in at approximately 455 kg and produces a respectable 145 HP. The "H" designates the

heavy-duty models, specifically designed for trucks and busses, as they don't exceed 2500 rpm. The last HR53 units to be built were fitted

with a much more modern VP D3-110 engine. The TAMD engine (see picture) is essentially a 6 cylinder 3.59 litre Volvo turbo diesel bus or truck

engine which has been "marinised". The engine is fitted with a hydraulic marine gearbox which is water cooled, as is the turbo charger. The whole

cooling circuit is long and complex. Especially if the boat has not been used for some time, it's a good idea to check the big VETUS water strainer,

where sometimes we need to add water to overcome air pockets which may have developed over such longer periods of non-use! We systematically check

that there's water coming out of the exhaust, having - by omission - succeeded in 'burning' one impeller in our beginning days of owning the boat!

The engine does have a turbo (a hi-tech feature in a 1990s marine environment, I would argue), yet on the other, there is a total absence of electronics (which in my view classifies it as pretty lo-tech). The black box with electrics on the engine (see photo - top left-hand part of the engine) mainly houses a relay to stop the engine by cutting off the fuel supply (there is no mechanical decompression as on the smaller VP engines I've owned, although I was recently shown where there's a mechanical cut-off valve for the engine). Like many older Volvo Pentas, our engine smokes. In fact, to be honest, at times it smokes quite heavily, especially when load is suddenly applied. This can be quite embarrassing when manoeuvring around in marinas (or in the Panama Canal, where Ngahue IV was accused of polluting Panama City's fresh water reserves), when you can even leave black deposits on the water... Nevertheless, compression tests on our engine have shown that she is OK. New injectors were installed in 2015 just before we took ownership of the boat in 2016 and the valves are regularly and properly adjusted. Nevertheless, James Bond would be jealous of us when we suddenly open up the throttle and produce great wafts of black smoke to escape from pursuing foes. Oil consumption, however, is extremely low and well within the tolerances for a 28-plus-year-old engine of this size and technology. In other words, the black smoke produced is un-burned diesel fuel... It's been argued that modern bio-diesel fuels also add to the smoking issue on these older engines that were designed for and relied on "greasier" fuels... Officially, the motor had done less than 1000 engine hours when we acquired the boat in 2016. With our sailing, we quite consistently average about 250 engine hours a year (both in European half-season sailing as in full-time live-aboard cruising). We therefore suspect significant and enthusiastic under-reporting from the previous owner as the engine control panel had a new rev & hour counter when we got her. It's more than probable that in reality it had done double that number before we got her... In 6 years of ownership we have officially motored more than the two previous owners in 20 years! However, as these engines are supposed to last at least some 10,000 hours, there's still lots of life left in her! Our local Volvo-Penta technicians (formerly Kant Marine in Nieuwpoort) gave her a clean bill of health after working several days on an extensive revision in June 2016, as did Yachtservice Van Swaay in Bruinisse. Others too who did extended services on her have commented on the excellent state of our engine. In fact, the Van Swaay technician who oversaw the re-launch of the boat in 2019 was decidedly enthusiastic about our engine, which apparently runs extremely smoothly and quietly! His opinion was backed up by the motor engineer, Dominique Fily, in Papeete who serviced our VP there (and who is a gentleman we can 100% recommend, should you ever need a diesel engine technician in Papeete)!

As far as we have been able to ascertain, the following parts of the engine have been renewed in more recent years:

> Starter motor - 2014

> Turbo and exhaust elbow - 2014, 2019 and again in 2025

> Intercooler - 2014

> Injectors - 2015

> The engine's "electronics" (relays and ignition) - 2016 (this was done for sure, as from here on we are the owners)

> The engine control panel (plastic plate; attacked by UV) in the cockpit - 2018

> Water pump, primary muffler and some of the exhaust hosing - 2018/secondary muffler in 2019

> The heat exchanger cleaned and de-scaled & the Valeo 60 Amp alternator fully rebuilt - September 2018 and April 2022

> The engine's control cables and the electronic alarm unit in the engine operating panel - June 2019

> The engine's primary muffler (again) the stainless Volvo Penta part having rusted through - November 2021/April 2022

> The engine's cooling circuit, heat exchanger were and heat sensors) cleaned/Replaced to give perfect 80°C running - April 2022

Working with this large if not complex engine - she

really does fill our engine room well (see photo) - has been a new learning curve, as the "beast" is certainly a lot bigger and more

intricate than anything we've had before. Because we do not like running a loud engine, it runs at low revs. Too low to avoid coking of

the exhaust, so we need to check and clean the exhaust elbow more regularly than other owners do (who run their engines at much higher

revs). Checks are important, as we experienced a frustrating "fail" in this regard when we were one day out of Curacao in 2018. But

generally speaking, our Volvo-Penta is an extremely reliable piece of kit. It always starts when you turn the key, which is my main

requirement. Furthermore, it can take a fair amount of punishment and still continue to work afterwards. And during our extensive

cruising, there've been occasions when we had the engine running for 2-3 days at a time (albeit at moderate revolutions), which it

does without any protest!

Propeller and prop shaft

The VP engine drives a very large 4-bladed Flexofold propeller which was retrofitted by the boat's second owner. We don't know how he

used the boat, but judging from our few conversations with him, we think that he didn't mind some heavy 'power' -motoring at speed.

We, on the other hand, prefer very quiet motoring, despite the risks of coking up the engine exhaust. We

really need to run her at 2200 Revs on regular occasions, which, unfortunately, we tend to forget. With a clean bottom, the boat reaches

a comfortable cruising speed of up to 7 knots in calm seas at some 1250-1300 revs (and uses around 4 litres of diesel per hour in the

process). This gives the boat a theoretical motoring range of some 1050-1100M in a calm sea. If you push the throttle as much forward

as you can, the boat will accelerate to 8.5+ (even 9!) knots (useful for dodging freighters in TSSs or 'assertive' fishermen). Noise

levels are said to be reasonably moderate, even at full speed! But they did disappoint me in 2016 as I was hoping for a much quieter

boat, certainly when bearing in mind the thick layers of sound-absorbing materials in the engine room... In any event, engine revs

will not get beyond 2300rpm (the limiting effect of the big prop, we suspect). The engine was originally rated at 2500rpm max and

145HP; we think we've perhaps lost 3-5% of our herd of galloping horses over the years, though at least two VP mechanics have told

me the loss is probably much lower...

The VP engine drives a very large 4-bladed Flexofold propeller which was retrofitted by the boat's second owner. We don't know how he

used the boat, but judging from our few conversations with him, we think that he didn't mind some heavy 'power' -motoring at speed.

We, on the other hand, prefer very quiet motoring, despite the risks of coking up the engine exhaust. We

really need to run her at 2200 Revs on regular occasions, which, unfortunately, we tend to forget. With a clean bottom, the boat reaches

a comfortable cruising speed of up to 7 knots in calm seas at some 1250-1300 revs (and uses around 4 litres of diesel per hour in the

process). This gives the boat a theoretical motoring range of some 1050-1100M in a calm sea. If you push the throttle as much forward

as you can, the boat will accelerate to 8.5+ (even 9!) knots (useful for dodging freighters in TSSs or 'assertive' fishermen). Noise

levels are said to be reasonably moderate, even at full speed! But they did disappoint me in 2016 as I was hoping for a much quieter

boat, certainly when bearing in mind the thick layers of sound-absorbing materials in the engine room... In any event, engine revs

will not get beyond 2300rpm (the limiting effect of the big prop, we suspect). The engine was originally rated at 2500rpm max and

145HP; we think we've perhaps lost 3-5% of our herd of galloping horses over the years, though at least two VP mechanics have told

me the loss is probably much lower...

One advantage of the Flexofold design is said to be that the folding mechanism is relatively well

protected against sea life encrusting itself on the folding blades and in the folding mechanism. This is a definite advantage in warmer

tropical waters, where sea life develops with gay abandon after only a few days. The first photo shows the prop after 22 months in warm

waters: unrecognisable as a propeller, but nothing got inside the folding mechanism, so the prop continued to perform reasonably well. In

our home port Nieuwpoort though, we have actually had one season (2021) where too much growth got INTO the folding mechanism and

successfully 'sabotaged' the prop into delivering less than ±65% of its potential (see second photo). On our travels, we managed also

to pick up a 5m piece of fishnet (we were motoring off the Galician coast) so we are not totally immune to accidents at sea, unfortunately!

As the first photo shows, our propeller looked a sad sight when the boat was lifted after 15 months in tropical (yes that strange brown

lump is indeed our propeller!!) waters.

One advantage of the Flexofold design is said to be that the folding mechanism is relatively well

protected against sea life encrusting itself on the folding blades and in the folding mechanism. This is a definite advantage in warmer

tropical waters, where sea life develops with gay abandon after only a few days. The first photo shows the prop after 22 months in warm

waters: unrecognisable as a propeller, but nothing got inside the folding mechanism, so the prop continued to perform reasonably well. In

our home port Nieuwpoort though, we have actually had one season (2021) where too much growth got INTO the folding mechanism and

successfully 'sabotaged' the prop into delivering less than ±65% of its potential (see second photo). On our travels, we managed also

to pick up a 5m piece of fishnet (we were motoring off the Galician coast) so we are not totally immune to accidents at sea, unfortunately!

As the first photo shows, our propeller looked a sad sight when the boat was lifted after 15 months in tropical (yes that strange brown

lump is indeed our propeller!!) waters. The second photo taken with the growth from Nieuwpoort (Belgium) on the propeller, it didn't open sufficiently to give a decent amount

of thrust.

The second photo taken with the growth from Nieuwpoort (Belgium) on the propeller, it didn't open sufficiently to give a decent amount

of thrust.

When testing the boat just before she came out of the water in September 2018, Van Swaay Yachtservice put on full power and discovered that the PSS propeller-shaft seal leaked. In truth, it leaked quite badly! Not that we'd ever noticed this, as the leak didn't show at the low power settings we tend to use. From his side, Laurens Van Swaay was quite surprised we'd never seen any water leaking through the seal. The whole seal was duly replaced over the winter and a spare rubber housing of the PSS seal is kept as spare for our circumnavigation plans.

The HR system of having foot-buttons at the steering pedestal to operate the Sleipner Sidepower 10HP bowthruster is very convenient and

allows for extremely simple berthing. The 10HP motor (rewired in 2015) also has a better, modern propeller, with little cavitation in the

thruster tunnel which is very deep under the waterline. It is therefore very quiet compared to our former HR43 which was very noisy! The

bowthruster is relatively effective at shifting the bow around.

It is only in 15kt+ side-winds that a

bigger motor would be useful. However, in 23-25kt side winds our boat starts leading a life of its own! The bowthruster then just whirrs

quite ineffectually as the wind picks up the huge Rassy bow... Only a stronger bowthruster (15HP models exist - or even two thrusters)

could remedy the situation. As the larger part of the house battery bank is situated next to the mast, the cable run to the bowthruster is

relatively short. The thruster motor therefore suffers from no significant voltage drops. Having said that, it is important to keep the

bowthruster prop clean because (again) in 2021 it fouled quite seriously in Nieuwpoort and lost at least 85% of its effectiveness.

It is only in 15kt+ side-winds that a

bigger motor would be useful. However, in 23-25kt side winds our boat starts leading a life of its own! The bowthruster then just whirrs

quite ineffectually as the wind picks up the huge Rassy bow... Only a stronger bowthruster (15HP models exist - or even two thrusters)

could remedy the situation. As the larger part of the house battery bank is situated next to the mast, the cable run to the bowthruster is

relatively short. The thruster motor therefore suffers from no significant voltage drops. Having said that, it is important to keep the

bowthruster prop clean because (again) in 2021 it fouled quite seriously in Nieuwpoort and lost at least 85% of its effectiveness.

The previous owner, Dr Bierhoff, removed the three protection bars that Hallberg-Rassy fits to all its thruster tunnels. Apparently these absorb about 10% of the thrust generated by the bow propeller. On our circumnavigation, the bowthruster has always been more than adequate to help us move the boat around in tight corners, or to reverse into moorings between two other boats, when essentially the thruster's role is to point the bow in the right direction so that the whole keel acts as a "rudder" to keep the boat on track...

Having seen how the modern generation of Rassies is also equipped with stern thrusters and can turn around on their own axis, we looked into the possibility of installing a stern thruster on our boat. The positioning of the skeg and propeller shaft as well as the steeply rising stern with its slim sugar scoop form all work against installing a (retractable or not) thruster. There is an HR53 (it's been for sale on a couple of occasions) with a smallish sternthruster incorporated in the fixed part of the skeg. Interesting though this solution appears, it seems to me to affect and weaken the solidity of the skeg (and therefore the whole rudder structure). Best not sone... Sleipner suggested fitting two external pods either side of the main propeller. This, with the required adaptation of the wiring for the current bowthruster and fitting an electronic rather than a manual throttle to the VP TAMD41 B/H makes the installation of a modern docking system quite complex and pretty expensive. As Ngahue IV remains perfectly manageable for one person - also in a tight marina environment - provided the wind conditions don't become too strong (cross-winds of 18-20 knots plus) we're still very much in a status quo situation on this one.

Rig and Sail-handling and Rig - Sails

When we acquired Ngahue IV, she was just over 20 years old. Much of the standing rigging was original, and our insurers at the

time, Admiral Insurance, rightly insisted that we replace all of it at our soonest convenience. As the

previous owner, Dr Bierhoff, had purchased a beautiful set of new parts for the genoa and cutter furling mechanisms from

Reckmann Rigging, we turned to this premium and reputable German company, whose Stefan Schwarz was very helpful

to advise us on the replacement of all our standing rigging in Kiel while the boat was still at Knierim Yachts for storage. He, and his colleagues at

the Reckmann company have always helped us very professionally since.

When we acquired Ngahue IV, she was just over 20 years old. Much of the standing rigging was original, and our insurers at the

time, Admiral Insurance, rightly insisted that we replace all of it at our soonest convenience. As the

previous owner, Dr Bierhoff, had purchased a beautiful set of new parts for the genoa and cutter furling mechanisms from

Reckmann Rigging, we turned to this premium and reputable German company, whose Stefan Schwarz was very helpful

to advise us on the replacement of all our standing rigging in Kiel while the boat was still at Knierim Yachts for storage. He, and his colleagues at

the Reckmann company have always helped us very professionally since.

Ngahue IV is cutter rigged; her rig consists of (situation spring 2023):

> Seldén mast with hydraulic in-mast furling (we have two motors which we alternate every 5 years - a reconditioned motor is kept as spare)

> Reckmann hydraulic furling genoa - model RF90 (fitted in 2009 - we had it reconditioned in 2016)

> Seldén hydraulic furling cutter stay - model 300H (fitted and commissioned in April 2023)

> Navtec hydraulic boom support/kicker and back stay tensioner (this is a separate manual hydraulic system and was fully rebuilt in August 2018)

> Harken carbon spinnaker boom on track attached to the mast (we had it shortened and added a protective anti-UV sleeve and with a leather patch where it could hit the shrouds)

All stays are 10mm rod rigging and all shrouds are st/st 1x19 wires of varying thicknesses - the two running back stays are Liros lines with

4:1 purchase Seldén blocks. The central hydraulic pump for the mainsail, cutter sail and genoa is a Lewmar Commander 20 unit,

which Hallberg-Rassy installed in the forward heads. During the 2018-19 winter refit, we added a filter in the hydraulic return line, which

more than doubles the lifespan of the hydraulic oil in the system. And for 2023, all hydraulics on board were extensively serviced with worn parts

(notably the hoses) replaced and hydraulic motors sent to their respective manufacturers for rebuilding. In a move to increase our sailing

convenience, we had our cutter sail changed from manual Reckmann furling to hydraulic Seldén furling. This operation turned out to be a lot more

drastic than we imagined; but it also allowed us to replace all internal hydraulic hoses before they could rupture. With time, some had deteriorated

quite badly. Pictured here the new distribution valves for 3 hydraulic motors instead of two...

All stays are 10mm rod rigging and all shrouds are st/st 1x19 wires of varying thicknesses - the two running back stays are Liros lines with

4:1 purchase Seldén blocks. The central hydraulic pump for the mainsail, cutter sail and genoa is a Lewmar Commander 20 unit,

which Hallberg-Rassy installed in the forward heads. During the 2018-19 winter refit, we added a filter in the hydraulic return line, which

more than doubles the lifespan of the hydraulic oil in the system. And for 2023, all hydraulics on board were extensively serviced with worn parts

(notably the hoses) replaced and hydraulic motors sent to their respective manufacturers for rebuilding. In a move to increase our sailing

convenience, we had our cutter sail changed from manual Reckmann furling to hydraulic Seldén furling. This operation turned out to be a lot more

drastic than we imagined; but it also allowed us to replace all internal hydraulic hoses before they could rupture. With time, some had deteriorated

quite badly. Pictured here the new distribution valves for 3 hydraulic motors instead of two...

If one looks closely at pictures of our cockpit, attentive readers will spot not the usual 4 winches installed by HR, but 7 winches, ranging from the standard huge and electric ST66s to a small manual ST40!The previous owner added two intermediate-sized mechanical Lewmar ST58 winches as well as the small Lewmar ST40 mechanical winch to service the mainsheet track. Although it is useful to have dedicated winches in all shapes and sizes for every conceivable sheet or line around the cockpit, this does mean that getting in and out of the cockpit requires lots of extra thought and dexterity because all usable walking space has been taken up by these extra winches! However, we did find that for downwind ocean sailing, the extra 3 winches offered power for the boombrake, the fore guy and the preventer and proved to be very useful additions made by Dr Bierhoff. We also discovered that with all those lines trailing all over the decks, the boat becomes a hazardous and very "trippable" place to walk around on...

The previous owner had invested heavily in a full set of carbon sails from the reputable German sail-maker Stade. However, as these would

not survive very long in the tropics we decided, after lengthy discussions with Elvstrom Benelux, to acquire a whole set of new EPEX sails

from them (pictured here during their first outing in the Belgian spring of 2017).

In Guadeloupe we met up with the then (Danish) HR48 North Star and compared notes regarding our EPEX sails. North Star's sails had actually s

started to delaminate after 2,5 years and the owner had had a strong but decisive argument with Elvstrom's head office (he had received his

sails directly from the Elvstrom main office) before receiving a replacement set. So we started watching our sails more closely than before

as we felt that the pictures of our boat crossing the ARC finish line (our sails had been used for just 5500M then) started to show as a set

of "beginning-to-look-tired" sails... Most of the UV strip on the genoa was already falling off. And although we were told

that these latest Elvstrom clothes didn't crease, our sails had been creased ever since their second use... Hmmm, a bit disappointing...

especially when you consider the price of a new set of EPEX sails! Like our befriended HR54 Mar-Jolie, we had another bad

surprise with our EPEX sails (for Mar-Jolie it was the genoa and for us the main): when handling and holding on to the sails, they ripped!

Definitely not an advertisement for Elvstrom EPEX quality at all! When it comes to replacing our sails, we'll definitely opt for a

traditional set of Dacron, Hydranet or Gitter-Spectra sails. These would have been a better choice after all, as indeed the Elvstrom

representative in Guadeloupe suggested, as have many others since...

In Guadeloupe we met up with the then (Danish) HR48 North Star and compared notes regarding our EPEX sails. North Star's sails had actually s

started to delaminate after 2,5 years and the owner had had a strong but decisive argument with Elvstrom's head office (he had received his

sails directly from the Elvstrom main office) before receiving a replacement set. So we started watching our sails more closely than before

as we felt that the pictures of our boat crossing the ARC finish line (our sails had been used for just 5500M then) started to show as a set

of "beginning-to-look-tired" sails... Most of the UV strip on the genoa was already falling off. And although we were told

that these latest Elvstrom clothes didn't crease, our sails had been creased ever since their second use... Hmmm, a bit disappointing...

especially when you consider the price of a new set of EPEX sails! Like our befriended HR54 Mar-Jolie, we had another bad

surprise with our EPEX sails (for Mar-Jolie it was the genoa and for us the main): when handling and holding on to the sails, they ripped!

Definitely not an advertisement for Elvstrom EPEX quality at all! When it comes to replacing our sails, we'll definitely opt for a

traditional set of Dacron, Hydranet or Gitter-Spectra sails. These would have been a better choice after all, as indeed the Elvstrom

representative in Guadeloupe suggested, as have many others since...

Note: in 2020 Elvstrom provided us with a new EPEX genoa and EPEX Mainsail. Taking delivery of these sails was a bit of a nightmare for the Elvstrom Transport department. But they successfully managed one delivery in Panama and the other (which should have gone to New Zealand) in the UK (just before the UK jumped ship and left the EU). Elvstrom says that they had some production issues in the days when our sails were made, which unfortunately led to incidents of delamination. Sailing in the tropics does put extra strain on hi-tech sails such as EPEX. So although EPEX sails are splendid to have, they are best not, in our humble view, chosen for a circumnavigation! By the end of 2022 our Genoa began to look like a mess again and the mainsail, which we had only started using in May 2022, had certainly lost the bloom of its youth!!!

For our first departures for our circumnavigation, we set off with the following sails, which - predictably - all come from Elvstrom. For future departures we would probably sail off with the 'secondary' (read Hydranet) sails and keep the EPEX ones bagged for use back in Europe:

> An old but until then practically unused Elvstrom hydranet mainsail with 5 + 3 vertical battens (which was part of the boat's inventory - from 2004)

> A new Elvstrom EPEX mainsail with negative roach and no battens for failsafe furling in and out of the mast (originally of 2017 - new one from 2022)

> A new heavy orange coloured dacron Elvstrom trysail for use in storm conditions - it has its own track on the mast (2017)

> An old Elvstrom hydranet Genoa (date unknown) as well as a new EPEX Elvstrom Genoa (originally 2017 - the new one from 2020), the former coming with the boat

> An old Elvstrom hydranet cutter sail (date unknown) as well as a new EPEX Elvstrom cutter sail (2017 - new UV strip in 2023)

> An old Elvstrom Gennaker with a sock & snuffer (date unknown), which also came with the boat (which we actually left at home in 2017 fearing it was too big for us to handle)

In effect this gave us two complete sets of sails, plus a down-wind sail (a Gennaker) to play around with. The size and weight of the sails we have chosen to keep from the original inventory and those of the Elvstrom sails that we ordered are still such that a small crew of 2 not very strong people can (just about) handle them. Our full reserve set of sails fits comfortably and neatly under the berths of the fore-cabin.

For our first departure, we stayed away from our Gennaker and the Code Zero that we had at the time. For our second departure, the gennaker still stayed at home, and only the North Sails Code Zero was taken with us. The previous owner must have done something strange with the lower furling fitting of the Code Zero because on second use it suddenly unscrewed itself and broke off! It took an hour's work to get it back on deck, via a dip in the Pacific Ocean... Kaerver, the maker of the fitting, quickly responded to our queries, indicating that our fitting (the one that we found on the Code Zero) was perhaps OK for an HR29 in light winds. But our HR53 is 7x as heavy!!! More thoughtful "hmmms" regarding our previous owner! The sail has since been donated to a friend. In Guadeloupe in 2018, we had our carbon pole adapted and shortened by a foot so that it fits over the guard wires (and we don't have to take it out of its mast-fitting each time we go about). The sailmaker also made a beautiful cover for the pole to protect its carbon structure from the sun: UV kills carbon! Being relatively "lazy" sailors, most of our sailing is done with just the sails that are bent on at the beginning of the season and therefore available at the push of a furling or winch button... This undoubtedly 'penalises' us on speed, as we were constantly reminded during our ARC travels. But coming in last for the ARC legs never bothered us too much as our main concerns are our personal comfort & safety.

Ground tackle

On Ngahue IV we replaced the original 55kg CQR anchor with a more modern

Vulcan anchor. This gives us a total of two main anchors:

> A 55kg Vulcan anchor - on 120m of 12mm calibrated Lofrans galvanised chain from 2022, as main ground tackle (this Rocna-derivate anchor is from 2017) > A 55kg CQR anchor as reserve (this was the boat's original anchor and its design dates back to 1930s; for years HR fitted CQR anchors) > We are still in the process of looking for a light stern anchor and have got rid of the ±25kg Rocna-like stainless steel anchor

at the stern - it's attached to 8m calibrated chain and has an extra 56m anchor line (which we'll recycle for the new anchor)

|

|

Our anchor and 120m chain weigh approx. 550kg and to drop this and raise it again, we rely on an old and trusted Lofrans Ocean windlass rated at 1500 watts. We had it serviced in Guadeloupe in January 2018, and again in Bruinisse in April 2022. The maintenance technician in Guadeloupe asked whether it had ever been serviced since 1995. Of course we had no answer to that question; I guess that anchoring wasn't a priority for the previous two owners... We replaced the anchor chain in April 2022 with a length of 120m properly calibrated chain (a poorly fitting new chain had been fitted in the U.K. in 2021). The windlass was completely stripped and rebuilt by Yachtservice Van Swaay in Bruinisse, so that we can anchor with confidence in up to 30-35 metres of water!

For heavy weather situations and just before embarking on the ARC and our circumnavigation we ordered from Ocean Safety in Southampton a parasail anchor as recommended in the Pardeys' Storm tactics handbook (and apparently "unrecommended" by the US Coastguard). Even though it is not our intention to be sailing in waters where big storms would habitually form, it is nevertheless essential to be prepared for everything (see for more details on our Preparing for the ARC page).

Teak decks, hatches and (opening) windows

Maintaining a beautiful teak deck remains as much a mystery to me today

as 33 years ago when I took possession of my first HR. With time, though, I have certainly learned what NOT to do. The decks

on Ngahue (I) were initially washed and scrubbed with Starbrite teak cleaner and brightener, and the odd dose of

teak oil. Which looked lovely when applied to the cleaned wood. But oiled decks often turned dirty and patchy soon afterwards

(as the wood absorbed the oil differently, according to its density). When I sold the boat after 12 years, the surveyor strongly

advised against this treatment and told me that I had been killing the wood with it, and pointed to one bad spot in the deck that

needed expensive attention. In November 2022 the first Ngahue was put up for sale by its then (we think) 4th owner, and her deck

looked great. However, the 4th owner, a Yachting World editor who knew something about boats, had put a new deck on her approximately

12 years before...

On Ngahue II and Ngahue III the decks were given the (strongly recommended by) HR-suggested Boracol treatment and very little else, except the odd soft scrub with natural green soap containing linseed oil. Confusingly, instructions for using Boracol vary depending on who you talk to. They range from 'apply a thick coat with a brush once a season', to 'vaporise a thin & diluted coat several times a season'. The first approach seems to yield a more lasting result and is what we do these days.

Boracol is deemed to be better for the longevity of the wood, and certainly a better approach than regular sanding of the decks, which seems to be a very popular approach in Belgium, the Netherlands and Germany (as we discovered when acquiring Ngahue IV - see more below). Sanding the decks certainly leaves them looking a beautiful brown wooden colour. But of course you will have removed 0.5mm of the 12mm or so of teak deck each time you do this. In our view this is a much too high price to pay for a deck that will look nice for a limited period only (usually a month or two at the most)! Also, if this method is used too often, your deck gets thinner and thinner, which then leads to the caulking standing proud of the wood, and the dowels popping out when the deck is wet.

Ngahue IV, because of the treatments endured under the 1st and 2nd owners only has about up to 6-9mm wood left on the walking deck (as the Germans call it) and a good 9-10mm deck thickness on the coachroof and on the Hard Top. Under our management, the decks have obviously continued to lose thickness; but this can now be calculated in micrometers and no longer in millimeters!

For a detailed feature page on my 2022-23 deck restoration, please go here (an ongoing page of this site commenced in November 2022).

Despite her age and the fact that she spent nearly 4 years in the tropics, the hatches and opening windows on Ngahue IV are

generally in very good shape. The previous owner replaced the original large hatches with new low-profile Lewmar hatches. Surprisingly,

just one of the opening windows suffered from what is often called 'crazing' (see photo). On several of the older Rassies that we visited

when looking for an HR53 to suit our circumnavigation plans, we saw boats where most if not all windows had become crazed. Two colleague

and befriended owners of the other HR53s in Nieuwpoort decided in 2023 and 2024 to refurbish all his hatches and windows and found, c.q.

used a specialist company in the U.K. 'Eagle Boat windows in Bury St. Edmunds) to do this work at a most reasonable price (compared to

a set of new windows and hatches). We gladly accepted his offer to take on our one small windows along in his refurbishment project. The

window got a new acrylic lens to replace the old 'crazed' one. One can clearly how Hallberg-Rassy uses Butyl tape to seal windows in the

coachroof. Despite being 28 years old, the seal held perfectly until I removed the window frame.

Despite her age and the fact that she spent nearly 4 years in the tropics, the hatches and opening windows on Ngahue IV are

generally in very good shape. The previous owner replaced the original large hatches with new low-profile Lewmar hatches. Surprisingly,

just one of the opening windows suffered from what is often called 'crazing' (see photo). On several of the older Rassies that we visited

when looking for an HR53 to suit our circumnavigation plans, we saw boats where most if not all windows had become crazed. Two colleague

and befriended owners of the other HR53s in Nieuwpoort decided in 2023 and 2024 to refurbish all his hatches and windows and found, c.q.

used a specialist company in the U.K. 'Eagle Boat windows in Bury St. Edmunds) to do this work at a most reasonable price (compared to

a set of new windows and hatches). We gladly accepted his offer to take on our one small windows along in his refurbishment project. The

window got a new acrylic lens to replace the old 'crazed' one. One can clearly how Hallberg-Rassy uses Butyl tape to seal windows in the

coachroof. Despite being 28 years old, the seal held perfectly until I removed the window frame.

One of our windows leaked and I couldn't see what was wrong. I managed to remove it and discovered that the previous owner has removed it before and put it back with loads of silicone sealant (most of it in the wrong places. It's been put back with an appropriate strip of Butyl tape in the right place. That should be the end of an annoying leak.

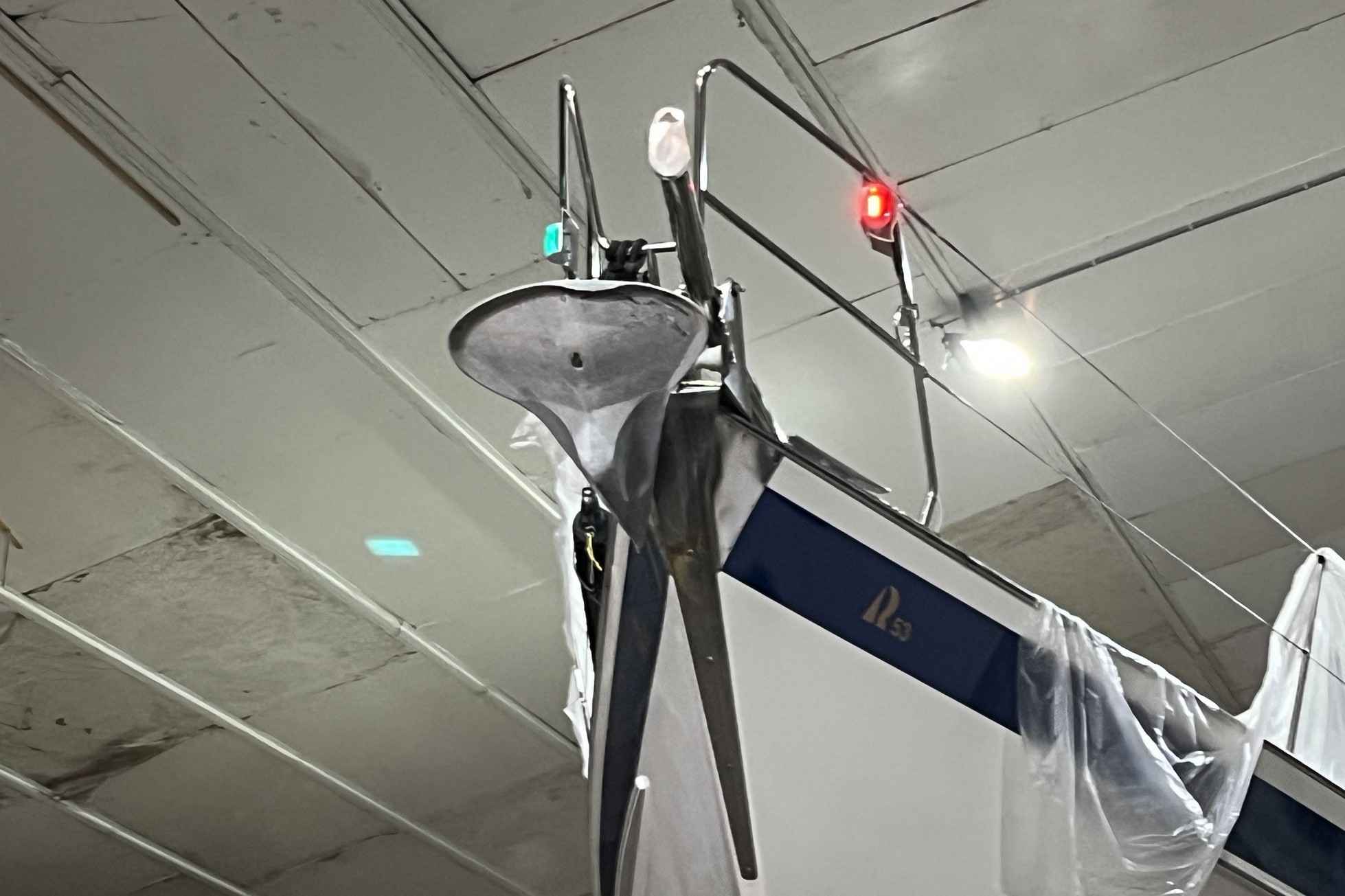

Navigation lights

At the end of the winter refit 2023-24, I decided to change our old Aquasignal, filament nav lights with a set of Hella marine LED

lights (designed and manufactured in New Zealand). The Hella lights come with a good metre of wiring added; which is connected to the

LED lights which are all in a sealed fitting. Simply fit the holder to the boat and clip in the light assembly. This makes the forward

lights completely impervious to seawater (which often played havoc with the old lights and their connections). We should no longer have

any bad surprises that the lower nav-lights are not on - or the filament of the bulb 'gone'. Replacing a 24V navigation light bulb is

pretty expensive too as the market is slowly thinning out!

All our navigation lights now are LEDs, with as only downside the fact that the special indicators for each light at the chart table no

longer function (they require a higher power draw than the LEDs use).

All our navigation lights now are LEDs, with as only downside the fact that the special indicators for each light at the chart table no

longer function (they require a higher power draw than the LEDs use).

Ventilation into the boat

Over the winter 2016-17, we removed the (Vetus) air ventilators that Hallberg-Rassy had originally installed in 1995 and that the previous owner had embellished by adding shiny chrome "horns" to vent as much air as possible into the boat. We decided we wanted to do our own "upgrade" to the deck and install the new generation of "Air Only" ventilators that the HR Yard (as do many other premium boat builders) fits these days. They are very good at keeping water out of the interior of the boat, so Leon Schulz of Regina Laska assured us. These ventilators (sold by a company based in Malta, manufactured in the Ukraine, with plastics from Germany) have an ingenious system of keeping water out with a lot of little yellow ping pong balls that seal off air openings towards the boat. A wonderful and simple design, BUT they are MUCH LESS efficient in channeling air into the boat compared to the previous generation of "trumpet"-shaped air vents. This is a pity in the tropics, where every breath of ventilation counts. Air Only does offer solutions for this, but they're not very pretty, or even silent, as it involves installing additional fans in the Air Only shaft! In hot climates, we leave the windows open and just need to keep a sharp look-out for tropical showers that suddenly inundate the interior of the boat. The new ventilators overcome part of the lesser ventilation issue by relying on a bigger hole in the deck compared to the old Vetus ones. To summarise our experience: in the tropics the "Air Only" ventilators are inadequate, but on the (very) positive side you do have a trip & stumble-free deck - and you are up-to-date as a "modern" Hallberg-Rassy...

After some months in the tropics, we noticed that several of the external domes of our Air Only ventilators started to go creamy under

the effects of the sun (when we signalled the problem, the manufacturer said this had been the fault of a well-known German chemicals

company that got the forumulation of its plastic wrong - we were promised replacement parts, which we finally fitted in Spring 2019).

From what we've heard, the Air-Only ventilators are certainly watertight; in our case this did put an end to the persistent leaks we

had around the fore deck Vetus ventilator (which had, it must be said in all fairness to Vetus, completely corroded over the years -

a fact we only discovered once I started removing the whole installation to fit a replacement Air Only).

After some months in the tropics, we noticed that several of the external domes of our Air Only ventilators started to go creamy under

the effects of the sun (when we signalled the problem, the manufacturer said this had been the fault of a well-known German chemicals

company that got the forumulation of its plastic wrong - we were promised replacement parts, which we finally fitted in Spring 2019).

From what we've heard, the Air-Only ventilators are certainly watertight; in our case this did put an end to the persistent leaks we

had around the fore deck Vetus ventilator (which had, it must be said in all fairness to Vetus, completely corroded over the years -

a fact we only discovered once I started removing the whole installation to fit a replacement Air Only).

The attached photo shows our uncluttered fore deck... The dark brown stains around the Air-only ventilators is where the original Vetus strumbox was fitted. The darker colour vanished after about 2-3 weeks when the boat was relaunched.

Poles on deck

Ngahue IV has two poles at the

back of the boat; both deck mounted and stabilised with a network of rods and guys attached either to the deck or the aft balcony. To

port we have a hefty stainless steel post supporting the Furuno radar scanner and various aerials (GPS - SeaMe, and electronic radar

reflector). To starboard we have a white Scanstrut pole supporting our Iridium IOP aerial. It was fitted in 2017. AST Communications,

our Iridium service provider, remarked that our IOP aerial was too low in relation to our radar scanner and that we needed a higher

pole. This was installed in September 2019. After a year or two, the paint started flaking off the pole, which Scanstrut has happily

proposed to replace (at the BOOT-Düsseldorf 2023 boat show). It goes without saying that we were very pleased with this offer! Getting

hold of the replacement pole was a bit of an adventure, as with Brexit, exporting goods from the U.K. to an individual consumer in the

EU is an administrative nightmare. The photo shows our aft deck and the old Scanstrut. Attentive readers will also note how the Iridium

IOP aerial has turned yellow over the years! We have also been warned to expect the aerial to fail in time... We will probably change to

a Starlink system when it does...

Ngahue IV has two poles at the

back of the boat; both deck mounted and stabilised with a network of rods and guys attached either to the deck or the aft balcony. To

port we have a hefty stainless steel post supporting the Furuno radar scanner and various aerials (GPS - SeaMe, and electronic radar

reflector). To starboard we have a white Scanstrut pole supporting our Iridium IOP aerial. It was fitted in 2017. AST Communications,

our Iridium service provider, remarked that our IOP aerial was too low in relation to our radar scanner and that we needed a higher

pole. This was installed in September 2019. After a year or two, the paint started flaking off the pole, which Scanstrut has happily

proposed to replace (at the BOOT-Düsseldorf 2023 boat show). It goes without saying that we were very pleased with this offer! Getting

hold of the replacement pole was a bit of an adventure, as with Brexit, exporting goods from the U.K. to an individual consumer in the

EU is an administrative nightmare. The photo shows our aft deck and the old Scanstrut. Attentive readers will also note how the Iridium

IOP aerial has turned yellow over the years! We have also been warned to expect the aerial to fail in time... We will probably change to

a Starlink system when it does...

Davits and dinghy

At the BOOT-Düsseldorf 2017 boat show, we looked at and decided to order a set of Swedish Batsystem

davits to be mounted on the stern of Ngahue IV. Most of the bigger Rassies have huge and solid Lewmar (or Simpson

Lawrence or Whittal) davits, mounted on special supports. These are indeed beautiful and impressive pieces of kit, often being

electrically operated as well, and capable of lifting hundreds of kilos at a time. We know, as we had a set of Whittal davits on

our HR43. And we saw several HR53s equipped with electric davits whilst searching for Ngahue IV. But these davits need a

reinforced transom and cut of the capping rail - this is what the Yard in Sweden, or Nova Yachting in Bruinisse do when

they install them with special support blocks. The main disadvantage, though, is that you place an enormous amount of weight at

the very end of the boat as the davits on their own are already very heavy. Perhaps with the more modern Rassy designs, and their

much longer waterlines (more boat in the water towards the stern and less 'unsupported' over-hang), you can afford to have a lot of

weight dangling over the stern without inducing any rocking-horse effects. With the more elegant HR53 shape, and her nice overhangs,

it seems to me that indeed you would be contributing towards aggravating such tendencies. The Batsystem davits simply rest on their hinges that you bolt firmly to the transom. This dispenses with heavy blocks and

reinforcements of the transom to support much heavier types of davits, like those made by Simpson Lawrence. Two blocks and tackles

(4:1 purchase) which are attached to the davits at one end, and to the pushpit at the other. They allow you to gently lift up the

dinghy in the davits - it's a simple lever movement. And marvelous simplicity! There is just one aspect to take into account though,

namely that Hallberg-Rassy makes its pushpits fairly lightly. This is important, because the Batsystem davits rely on the stiffness

of the aft balcony to hoist the davits and their charge into the upright position. We knew that we would need to strengthen and

rigidify ours. When Maricom installed our communication electronics, and notably the Iridium aerial on a Scanstrut pole on the aft

deck (see elsewhere on this page) they proposed to make up two struts to stabilise and rigidify the pushpit. If you look closely at

the left picture or our boat, you will see the Batsystem davits and the two struts that were bolted to the aft balcony so that it

has become significantly more stable. When we picked up an unmarked and submerged lobster pot in Guadeloupe and needed to launch the dinghy in slightly choppy waters

to cut the line, the rocking movement of the boat put the dinghy in the water at the low end of the swinging movement, and then back

up in the air the next moment. This jerking movement put so much stress on the aft balcony that despite the Maricom reinforcements

the port and starboard balconies twisted out of shape. So we asked for additional struts to be made up and hold the pushpit in place

from the other side (see picture on the right). Guadeloupe being French, we learned that these struts are called "bras de force" in

French (arms of strength); a rather apt name. The result is that our balconies have become indeed QUITE RIGID now. They are

sufficiently rigid enough for our need for stability at the back of the boat. In two of the three pictures below you can see the

reinforcement struts for and aft of the balcony. The first picture shows just the initial deck reinforcement fitted by Maricom which

was not up to the job - alone - to rigidify the aft balconies. The Batsystem davits, even with our dinghy in them, don't interfere hugely with the Watt & Sea water generator that you need to drop

into the water at the back of the boat... It remains difficult though as it not easy to slither between the dinghy and the stern to get

to the bathing platform... After some discussion with the Batsystem people at the 2019 BOOT Düsseldorf show, we managed to tweak our

davits and adapt Poutini (our dinghy) to simplify operations. Our new Poutini (a Columbian built AB dinghy which from 2022 replaced our

original Pischel Bolero is much smaller (the AB website is: AB Inflatable dinghies).

It sits better in the Batsystem "arms". A first trip to the top of the North Sea and back in May 2022 seemed to indicate that we are on the

right track - see last photo. We tinkered a little more with our set-up during our 2022/23 winter lay-up as especially the cover over our

dinghy rubs away where it touches the davits' arms. We will also lift the dinghy a little higher so that it is well clear of any following

seas.