|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Narrative accompanying the pictures above - for the first half of 2019 - Starting at the top left-hand corner...

At least once a week over this whole winter refit-period, we tried to spend a day working on the boat. As you can see, after removing the plastic sheets

that 'Team Van Swaay' put over the boats they keep in the 'bootloods' (= their boatshed, or covered boat storage building) in Bruinisse, the general mess on

deck becomes quite clear to see. Although I do spend regular hours trying to clean up the deck and cockpit so that you get a better overview of what is

where. In addition, we go to the boat "armed" with a to do list for the day, so that time in the "loods" is spent as efficiently as possible. Lots of bigger

and smaller things have been improved over the 2018/19 winter (see the We're off circumnavigating page number 6) for extra details. Like screwing down the

strips in our entry gates again and putting more m¨odern and cleaner deck filler caps on the boat. As we moved into the second half of February 2019, Yachtservice Van Swaay reassembled our propellor and fitted a new PSS Shaft Seal from PYI Inc in

the US; as described elsewhere, the old seal leaked quite badly when you put on full power. I changed the membranes on our Jabsco & Henderson bilgepumps,

and I contacted a specialised metalworks company in Belgium to see whether we could improve on the connector pins for our hydraulic steering rams. We're on

to a good and solid solution with them. After a lot of faffing around, we finally managed to sort out our cockpit charttables, which now have new base

plates and 6 layers of varnish. The old Victron battery charger took some work to be removed from under the central berth in the aft cabin. To facilitate installation of the new (and

identical) charger, I prepared the unit at home (see photo) so that inserting each of the many the existing wires into the right slots in the charger shouldn't

be a complete nightmare. It thus became a manageable job and the new charger sits where the old was, with as only difference that it has been through-bolted

to the bulkhead... Bulbs in the steering pedestal, though, are proving a bit of a problem: to find, identify and to renew... So what we've done is replace

the one (green) bulb for the bowthruster on/of switch with its LED "brother"; and we will fit a separate small directional LED bulb (seen here lying on top

of the pedestal) that will light up the sail furling buttons. That way, at night, when the compass light comes on, we can also easily see which buttons to

push to furl or unfurl the main or genoa. That was a bit of a problem on our previous Atlantic crossings. Yachtservice Van Swaay is also replacing a number of not so-fresh-looking through-hulls and seacocks and adding a completely new through-hull/seacock

with water filter pot for the Westerbeke generator so that it will get its own seawater inlet (and no longer have seawater cooling issues)! Meanwhile I have

removed the bronze fitting around the rudder stock so that it can be adapted by a specialised company in Deurne (Belgium) for taking heavier and more solid

connector pins with the steering rams. Twice a year you regret the size of your boat: once when polishing the hull (there is lots of it) and once when

anti-fouling the bottom (still to come - and there's lots of that too). But the resulting shine gives you a great sense of accomplishment. In March we

also drove through heavy rain and pretty stormy winds to go to Eemnes, near Utrecht in the Netherlands, for a weather at sea course. When you start to find

that you don't learn too much from a course which was pitched at the higher level of knowledge, you can be confident that you're beginning to get things under

control! Whilst we were improving our meteorological knowledge, Yachtservice Van Swaay was busily improving our gas installation, using some of the parts we had

brought back from Sweden in September 2018. This'll now be OK for at least two years - we just need to keep the seawater and moisture out of the system

(copious use of WD40 to spray a protective film on the various parts). We then spent one of our Bruinisse working days, polishing the boat's stern and all

the stainless steel things attached to it. Quite a job. Also, all nav lights have been removed, cleaned, and given new wiring through new deck fittings.

The sacrificial plastic sleeves that Hallberg-Rassy fits at the Yard had either disappeared or hidden themselves inside the pushpit or pulpit tubing. After

a lot of unhappy moments, merrily punctuated by the appropriate bad language reputedly used by sailors, everything has been cleanly fitted. All blood from

a gash in my left finger (a screwdriver went through said finger) was removed as well. HR hides its wiring runs well, and it is only at the final point when

wires have to go through a bulkhead to reach a connection box inside that you can actually see your wires - here's me sitting in (or more accurately, wedged

into) the anchor well, trying to lead the wires to their destination. Of course the wiring inside the boat isn't any easier to do (courtesy of the

gorilla-octopus workers of the Hallberg-Rassy Yard). But the end-result on both sides is very satisfying, with a new and thicker sacrificial used to stop

the electric wire rubbing against the pulpit and/or pushpit and a reasonable amount of extra wiring looped together next to the internal junction box. We

also added two new white plastic bushes to the bathing ladder - surprisingly, the screws holding down the clamps just seem to be screwed into the hull.

Anyway, it works and the ladder is now firmly fitted with two new bushes so that it doesn't rattle in the holders anymore! Another job on the "todo" list

to tick off... Meanwhile, at home, we haven't kept still either. The varnish on the cockpit table has been touched up, the bow boarding ladder cleaned and given new

protective tubing (the old tubing had peeled off), and two full days were spent at the computer correcting all paper charts up to April 2019. The next session

will be on board... And in Bruinisse as our neighbours are heading for the water, we're beginning to see more and more of our boat! By early April, very few

boats remained in our company, though on one Saturday Robbert-Jan Poerstamper (of HR43 Nelson and President of the HR Connectie) was busily glossing the polish

on his hull whilst we were fitting nets around the aft deck (so that we and our bits and pieces stay on board when the boat wallows across the Atlantic, as she

will later this year. Bit by bit we are improving our boat and getting her ready for our renewed circumnavigation, even if our jobs-list is like a mirage in the desert: the end

always just out of reach. At least the gulls flying around the Zeelandbrug in the evening don't seem to care much about our troubles as we drive back

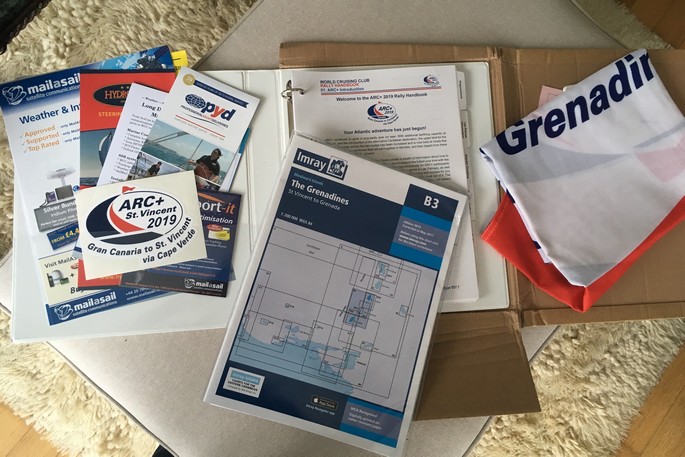

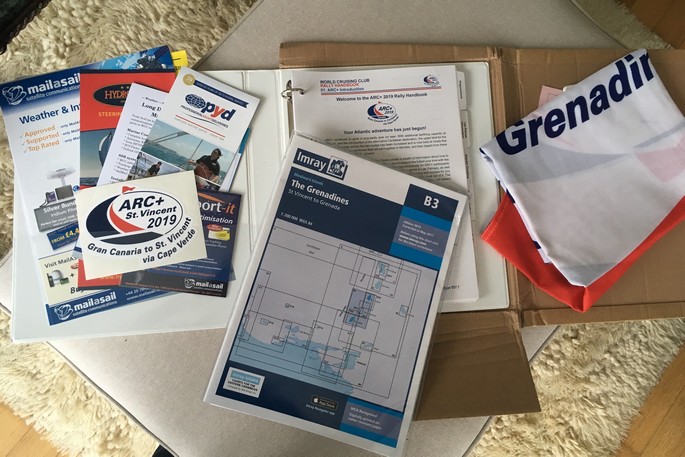

to Brussels. And to motivate us a little more, WCC sent us our ARC Plus Rally Handbook early April 2019! A couple of days later the World ARC Rally Book

arrived too; in between we further cleaned and worked on the boat and prepared her for her several coats of anti-fouling paint. There was a period of really

good weather around Easter: this proved to be ideal to get two coats of anti-fouling paint on the boat, and to take our outboard engine home and do some

maintenance work on it on the terrace... There's also a picture here of Poutini's new anti-UV clothes!! At the end of April we had more or less done all our anti-fouling: 4 (!) layers of high performance light blue paint. Now Laurens Van Swaay could move

the boat outside, so that he and we could complete the last items on our "to do" list. June will be "testing month", and July loading up and getting the boat

(domestically) ready to set off again. We will have been away from ocean sailing for nearly 10 months, 9 of them working on the boat, which is now in a much

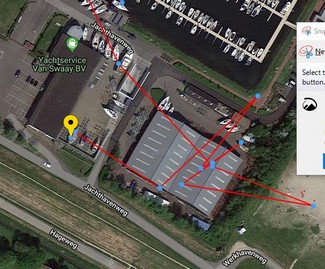

better state to set off than in 2017! But before then, there's still a lot to do... The boat hall in Bruinisse is used as a car park during the summer months, so, much to our regret, we knew that Laurens Van Swaay had to move the boat

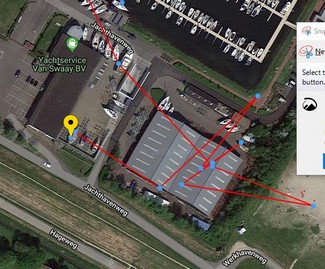

outside. We activated our Yellow/Brick tracker and were astonished to see the various positions of the boat before she was quietly put into her working

berth next to the Van Swaay Yachtservice offices. A case of suffering from "la cucaracha"??? With the boat parked outside - looking a little like a landmark

for Yachtservice Van Swaay - the last series of jobs are tackled. Much to my surprise, the outlet hose of our electric toilet was more or less completely

blocked. Well, with a new sanitary hose at least the toilet will make fewer funny noises... Our steering block came back from Dirk Roegiest, complete with new

and heavier pins. It may look identical to how it left the boat 2 months earlier, but it has been strengthened and much better and thicker connector pins

inserted. And Team Van Swaay is steadily doing maintenance on the 3 junction boxes of our Whitlock steering system. So we should be able to have full and

100% faith in our steering system and autopilots to get around the world without any hick-ups... With the settee cushions removed for refurbishment, we had

easy access to the storage areas under and behind the seats in the saloon and aft cabin. This was therefore an ideal moment to sort out the things that are

normally stored here and update the storage plans and plastify them for easy reference once we're sailing again! As some slightly sunnier and warmer weather returned to Bruinisse in May, Team Van Swaay attacked the saloon, removed the floor boards and added hard wooden

bungs around the water tank so that it won't "boink" out on the open ocean. A few days later, the saloon floor was back again, and I could start cleaning the

woodwork and those bits that are usually hard to reach. Team Van Swaay also replaced the aft holding tank's safety valves and removed the bow roller fitting

which they sent off to a specialist welding firm for reinforcement and improvement. This was the fitting that had been damaged in Guadeloupe and repaired as

best as possible with the mast still up. Now it was not only repaired properly but additionally strengthened for safe anchoring in all circumstances. One of

the new clutches leaked during some heavy rain, so it was ripped off the deck and put back with treble portions of butyl tape! And back inside, Team Van Swaay

struggled to remove the old washing machine (they suspect it had been installed via the cockpit locker) and install a new one. The simplest way was to enlarge

the hole in the wall; install the new machine; and redo all the woodwork as before and fit a larger Corian door instead. All in a day's work for them. Launch

time will be coming soon... But just before then, the revamped bow-roller came back from the welders, our anchor chain was marked, and we suddenly and pleasantly found ourselves in the

company of our friends Frank & Astrid Huis' HR54, Mar-Jolie. So, as a Ngahue IV exclusive news item, we can show above two pictures showing the design

evolution of HR yachts from the 1990s to the early 2000s! Pretty revealing anout achieving longer water lines and faster boats! Only a day later Team Van Swaay

let their "toys" loose on the boat and she was quickly put back in her element after 8 months of refitting and revamping. Lots of checks now needed to be carried

out; which was quite necessary as so many things had been done during the winter. A connection not made to the new alternator meant this was not charging the

batteries -> re-attach the loose wire and problem fixed! A loose refrigerator lid had nothing to do with loose screws, but a broken hinge. An urgent order sent

to Mellie Rassy at Shop HR and two hinges are in the post to us. A fan in the engine room sucked instead of blowing. Reverse the wiring and again problem solved.

The forward electric toilet's wiring was also crossed - swap around one yellow and one brown wire and the issue was solved. And so the list goes on... And with

all the activity on the deck, a couple of old dowels came loose - replacement needed (but we have a whole box of spares thanks to Mellie Rassy!). Wednesday 5th June was planned for a test-sail with Laurens Van Swaay and Jesse, the Rigger, both being present. The only absent partner was the wind, so we

postponed the test-sail for about 2 weeks. With most jobs on the boat being done, we could make the long trip across the Eastern part of the marina and

moor Ngahue IV in her new and temporary berth on "J" pontoon. Just one leaky connection under the kitchen sink remained to be sorted out. And Jesse, a man

of many talents, will clean up some of the deck seals that have gone soft under the tropical sun. Meanwhile, I have been going through all my own check-lists

to make sure that everything on board is working as it should. In all the boat was laid up "inside" for about 8 and a half months. Which is a long time to

forget how everything works - or worked until September 2018. And we need to get the software in all navigational equipment that relies on "IT" to be updated

to the latest version! A very fastidious job that's scheduled for early July with Sirko Feldbinder of Mare-Multimedia in Germany. I wonder how global navigators

with even more electronics on board than us get along... Two days later, Re-style from Steenbergen came on board to fit the new cushions. The new cushions are made much more solidly than the previous set which came

from a company in Belgium. But making cushions in your workshop and getting the same perfect fit on board is always going to be a challenge, especially on an

older design with all its quirky curves and corners. Consequently, some of them had to go back to the workshop for small alterations. Well, on this picture the

saloon is beginning to look a bit better than when all cushions were removed - but things are still in a big jumble. The "Final fitting" took place a week

later. Bas Girmscheid and his team now just need to come back for some final tweaks on two of the cushions that are misbehaving... But the general and final

view is very pretty. Meanwhile, when browsing the site of Mare-Multi-Media, the company that originally fitted the new Furuno electronics on our boat in May

2016, I found this picture of Mr Feldbinder and our boat in Kiel - a bit of a throw-back to Ngahue IV's early days and a nice souvenir... The Hallberg-Rassy Connectie organised a get-together with Nova Yachting, the Dutch Hallberg-Rassy dealer. A trip from Bruinisse to Zierikzee, which in distance

isn't too far away, but does involve going through a lock and under (through) a bridge. The whole group got together the evening before for a "greet & meet" party

and a group photo. But the next day the weather was as foul as ever. The abundant rainfall had even gone through a deck fitting and dripped on my pillow throughout

the night... Pictured here is a Hallberg-Rassy 36 rafted up to Ngahue IV, waiting for the lock gates to open. Entering Zierikzee at LWS is challenging with

a 2m30 draft (actually 2m29 with an empty standard boat - but Ngahue IV is no longer standard and far from empty...). We thought we'd have no problems leaving on the

Sunday morning, but our newly anti-fouled keel was only centimeters away from the sandy bottom of the channel! And good practice for eneterring the marina on Saint

Vincent where apparently we will require special pilotage to get in by daylight! A wonderful weekend, even if it did start with lots of rain: our foul weather gear

got a shock that it was getting used again after nearly 3 years!!!!! Interesting to look at a picture I downloaded from the Hallberg-Rassy site which extensively

posted on this event: it shows us moored outside 3 HR48s, which definitely look bigger than our HR53. Again proof of how boats have evolved over the years... I "attacked" this dripping deck fitting soon afterwards and re-bedded it with even more Butyltape and Sikaflex than before. Captain Messy at work! But hopefully

there will be no more drips on my pillow... And a humorous picture of an Easter Island statue, seen in the major German DIY store where we collect our new gas-bottles

from for the boat. Little does the store staff know that when we return our bottles they've travelled just a little bit more than other bottles... Bit by bit the

interiour of the boat is being readied and all the things that we believe we'll be using this time round are being stowed or re-arranged so as to be easily accessible

when we need them, as here for instance in the forepeak (Note how our Code-0 is now ready to go out the hatch and be hoisted quite easily)! On our first trip it was

stowed under the berths and never came out because of all the fuss just to get access at it... July 2019 progressively became a cheerful, hectic and worrying period. Cheerful as we happily crossed off the last items on our "To Do" list. Hectic

as we realised that we still had a number of "other" things to do than prepare the boat. Worrying as everything seemed too simple and we kept looking left

and right to see whether we weren't missing anything crucial in our preparations. A positive sign is when you walk into the chandlers and can't find anything that

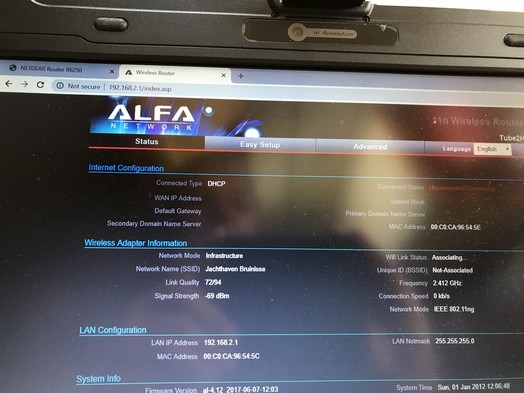

you really need for the boat anymore. July was also "struggling with software" month. Mr Feldbinder (see above) returned on board to update our Furuno plotters

and FI70 instruments. What should have been a simple operation turned into a 6-hour ordeal, taxing man, computer, Internet and said instruments to the maximum.

But in the end our plotters were super up to date, the instruments updated, and the latest versions of our electronic charts loaded. Internal organisation continued,

and ended when even the cockpit locker was re-organised and a a small picture made showing where everything is. Our deck caulking, which the previous owner had largely changed, had obviously suffered from the tropical sun and was slowly turning to sticky tar, leaving nasty

black streak on your feet and the deck when walking over it. Team Van Swaay worked on the port deck, whilst I attacked the deck seams on the aft deck. If the new

caulking is as successful on the wood as it was on my hands (forgot to put on gloves), then it should be fine! Also a detail picture of the engine room, which

is now really looking nice and "professional" with all the work & maintenance done by Team Van Swaay. Note: All our further activities from here on (from 1st August 2019) are described on our Circumnavigation pages - please refer to this link

We're off circumnavigating and read on from Page 7.

Return to Photogalleries Start page